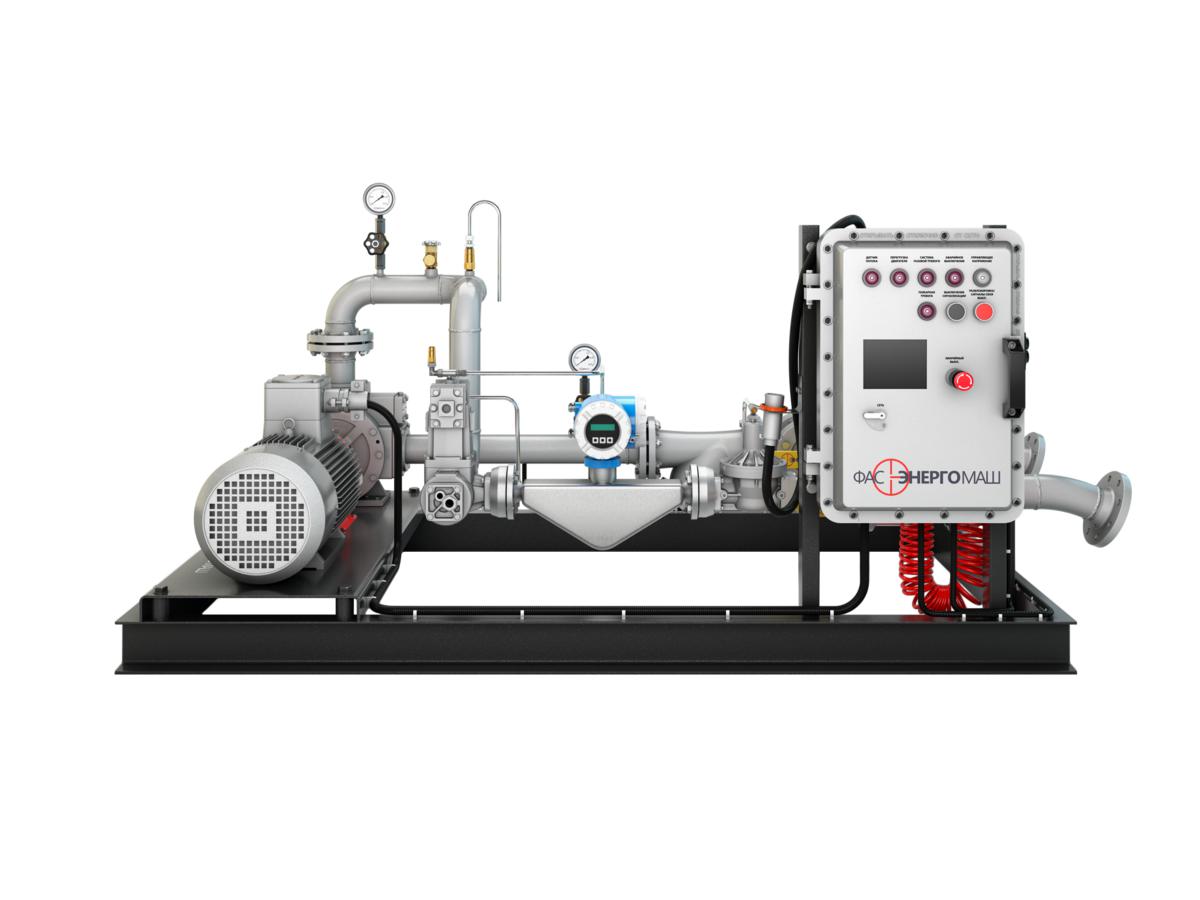

Modular Process System of the Pump-Counting Unit

A modular process system of the pump-counting unit with a capacity of 490 litres/minute manufactured by FASENERGOMASH, LLC.

System Components

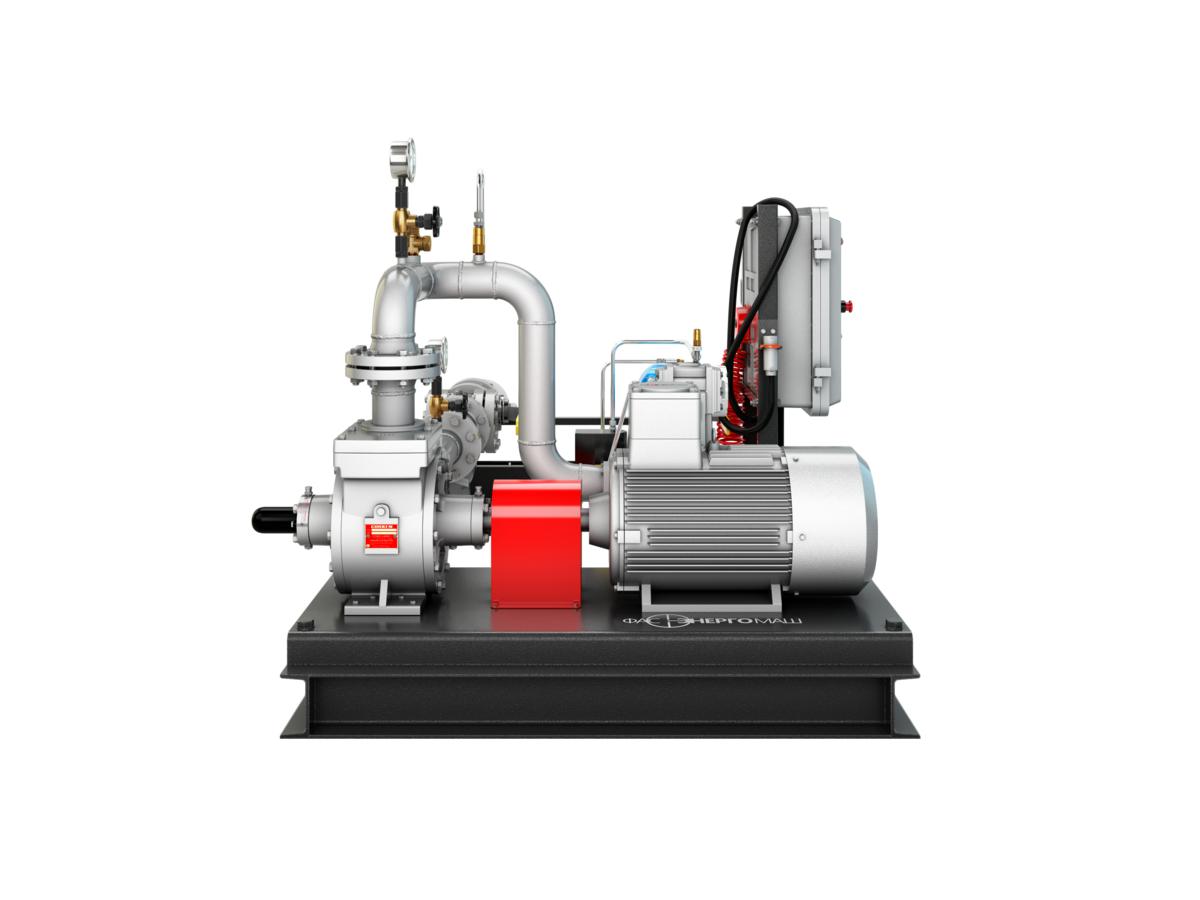

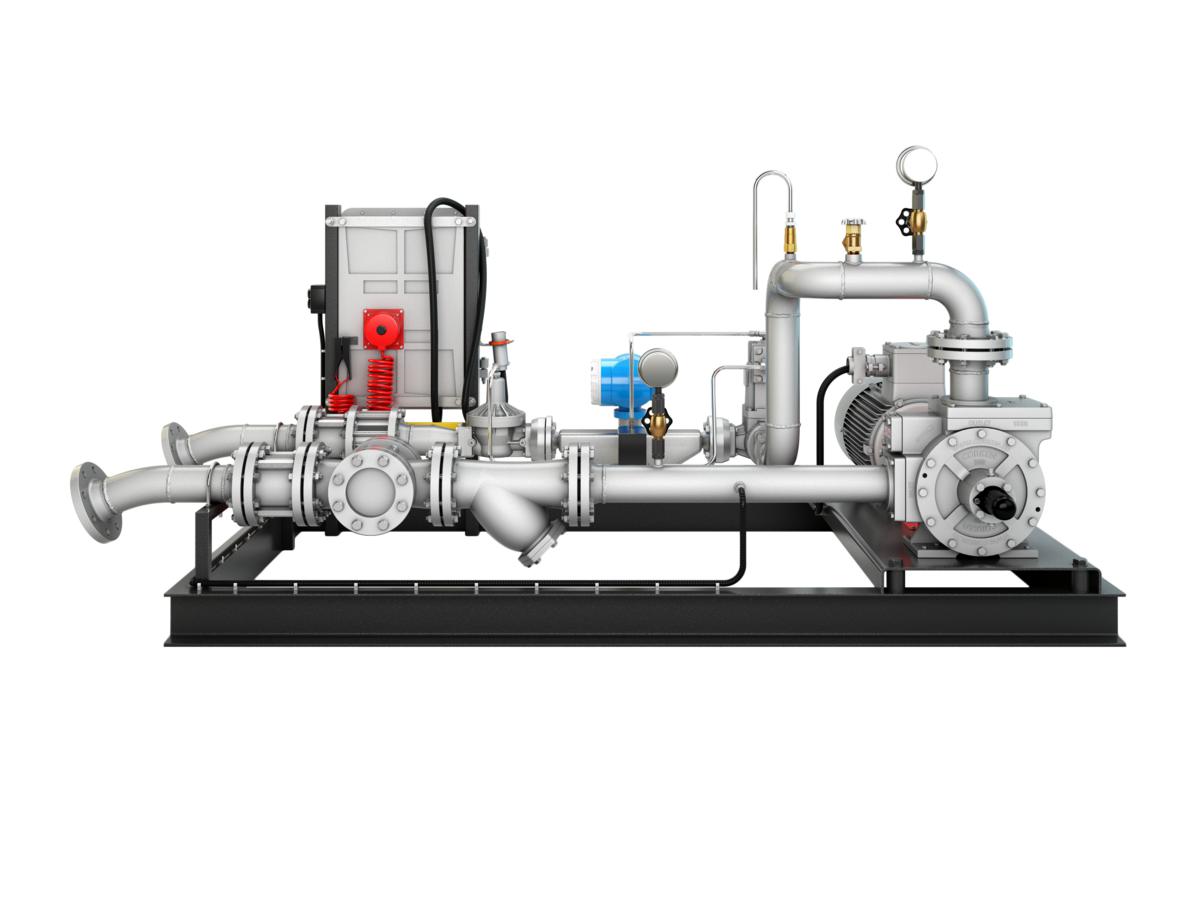

- FAS – LG pump. The pump is completed with an explosion-proof motor of 11.0 kW, 400/690 V, 50 Hz, E Exe II T3, max. capacity of 490 L/min at a differential pressure of 5 bar, max. differential pressure of 10.5 bar, is mounted on a common steel frame, primed and painted.

-

FAS pump manifold system. Input: Flange DN80 (completed with a mating flange). Output: Flange DN80 (completed with a mating flange). Comprising:

Discharge line DN80 completed with:

- Pressure gauge with a shut-off valve;

- Back-draft damper DN80;

- Ball valve DN80.

Stabilizing line DN80 completed with:

- Strainer DN80;

- Inspection window DN80 (visual flow control device);

- Ball valve DN80;

- Pressure gauge with a shut-off valve;

- Relief valve;

- Angle bleeder valve;

- Dry-running sensor.

-

LPG mass counting unit, 2", PN25, completed with:

- Gas separator with a fine filter;

- Special mass counter to measure mass and volume;

- Differential valve;

- Input 2";

- Output 2”;

- Rated capacity: 490 L/min.

-

Electronic counting device consists of:

- Power supply unit 20–55VAC / 16–62VDC;

- Digital display;

- ON/OFF unit;

- Amplifier for the product movement control sensor;

- Vapour phase return line DN20 with a ball valve and flange fitting M 60x4, left-hand.

- Electrical control panel for mounting in an explosion hazardous area (a power connector of explosion-proof design for connecting an external feeder is mounted on the panel casing). The system for automatic heating of electrical control panel and pump casing intended for operation in low-temperature regions.

The modular process system is factory-assembled and frame-mounted, primed, and painted.

* The arrangement of elements may differ from those shown in the pictures. FASENERGOMASH, LLC reserves the right to introduce technical changes.