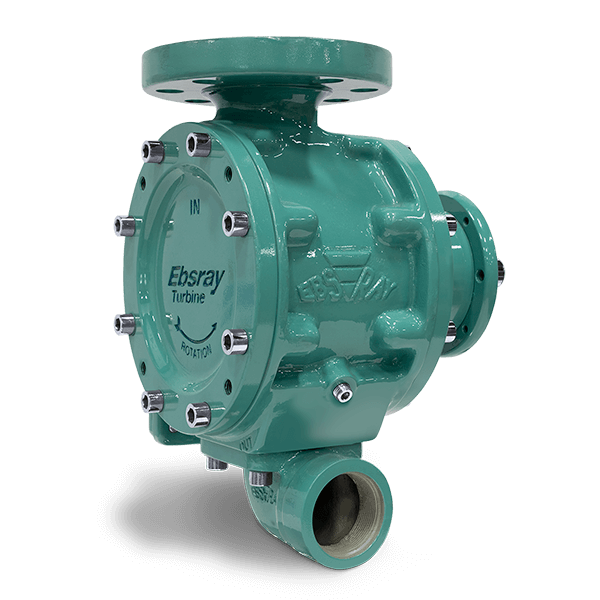

R75/R77 HiFlow Series of Regenerative Turbine Pumps (up to 600 l/min)

The R75 & R77 Ebsray HiFlow Series of Regenerative Turbine Pumps are large truck transport pumps loading and unloading of LPG, propane, butane and Autogas applications. These LPG truck flange mounted pumps are built for the rigors of fluid delivery and are driven by either electric or hydraulic drive or high-speed PTOs.

For fast, smooth, and quiet transfer of fluids, the HiFlow R75 & R77 Series Pumps provide much need speed and efficiency in the time sensitive nature of deliveries. Both pumps feature a 3-inch inlet port flange, 2-inch discharge port, and a 2-inch auxiliary inlet port and operate within the speed range from 2,100 to 3,500 rpm. The R75 features flow rates of 150 to 500 L/min and features an integral bypass valve. R77 offers increased flow rates of 180 to 600 L/min.

Elevate your LPG truck transfer operation with the Ebsray R75 & R77 HiFlow Series of Regenerative Turbine Pumps, the new high flow LPG truck pump.

LPG Pumping Challenges

LPG is a notoriously difficult to pump due to its material characteristics. LPG, whether butane or propane, is unique in that it can be transported and stored as a liquid, but when released it will vaporize and burn as a gas.

When liquefied, LPG gases are always at their boiling point at normal temperatures. The slightest drop in pressure or the least addition of heat will cause them to boil and give off vapor or gas. Any liquids that are at their boiling point often offer cavitation challenges when pumping transfer begins. And cavitation in the wrong pump can have devastating consequences for not only the pump, but the system, and the total operation. Ebsray Regenerative Turbine Pumps are extremely well suited for the pumping of LPG with the ability to operate under conditions of cavitation delivering smooth non pulsing flow, its whole life and not suffer any additional wear or damage and its operational life will not be affected in any way.

Features and Benefits

- Can be driven by either electric or hydraulic drive or high-speed PTOs

- Both models feature a 2-inch auxiliary inlet port, 2-inch discharge port, and 3-inch inlet port flange

- High differential pressure of 14 bar (203 psi)

- Operates at speeds from 2,100 to 3,500 rpm

- The R75 features flow rates of 150 to 500 L/min and features an integral bypass valve. R77 offers increased flow rates of 180 to 600 L/min.

- Features integral bypass valve set at 14 bar (203 psi) – (R75 model only)

- Single-stage Ni-Resist impeller provides unmatched operation, along with durability and long life with no performance drop

- Balanced multi-spring carbon vs. silicon carbide mechanical seal provides years of trouble-free service

- Wide temperature operating ranges from -40°C (-40°F) to 100°C (212°F)

- Cartridge seal arrangement allows simple replacement of mechanical seal assembly, from the front of the pump without the need to disconnect the pump or drive

- Sealed for life bearings require no routine maintenance ever

- 300# ANSI flanges and full ductile iron construction making the pump robust and giving a maximum working pressure of 30 bar (435 psi).

Advantages of Ebsray Regenerative Turbine Technology

- Operates without a Best Efficiency Point (BEP) meaning that Ebsray Regenerative Turbine Pumps have the performance curve flexibility of a positive displacement pump

- Diminishes the damaging effects of cavitation by smoothing the fluid. Due to the regeneration of the liquid that happens within the cells of the impeller, the pump takes the vapor bubbles and collapses them gently allowing for smooth and gentle operation of the pump

- Excellent self-priming and vapor handling abilities for trouble-free handling of saturated and boiling liquids

- Will operate without vibration and noise in all pumping situations, even during cavitation conditions

- Smooth pulsation free discharge of fluid that is gentle on the whole pump system with inherently soft hydraulic characteristics

- With MAWP to 29.3 bar (425 psi), regenerative turbine pumps work with liquids with high vapor pressures

- Low NPSHr, more forgiving on difficult suction conditions such as low NPSHa and cavitation

- Designed for continuous duty applications

- The only wear component is the mechanical seal. Every other component is non-contact component.

- Small compact footprint when compared to competing technologies.

- Durable construction designed for continuous duty operation

- Field serviceable – repairs can be done in the field

- With few moving parts, Ebsray Regenerative Turbine Pumps are less complex to operate and maintain, as well as to repair and rebuild, due to easy access to the seal and impeller

- Single-stage pump engineered to perform reliably, safely building pressure at the motor speed and transferring fluid at that pressure

- Wide performance range within various environmental conditions allows for system flexibility and many different configurations

- Less operational costs due to a highly efficient pump that requires a smaller motor than other competitive regenerative turbine pumps

- Increased flow rates with more throughput and faster loading and unloading times when compared to side channel, vane and centrifugal pumps

- Simple easy installation that requires no additional adjustments, liking shimming, needed in order to maintain performance

- Motor interchangeability, Ebsray Regenerative Turbine Pumps do not require proprietary motors and allow for flexibility in motor options

- Viscosity flexibility range from 0.1 to 50 cSt

Technical Data

Available Models

- R75 (flow rates 150 to 500 L/min)

- R77 (flow rates 180 to 600 L/min)

Porting

| Porting | |

|---|---|

| Inlet Port | DN80 (3") ANSI Class 300 Raised Face |

| Alternate Inlet Port | 2" Flanged (2" NPT adaptor available) |

| Outlet Ports | 2" Flanged (2" NPT adaptor available) |

| Gauge Ports | 1/4" NPT |

Materials of Construction (MOC)

| Part | Material |

|---|---|

| Body, Cover, Bearing Housing | Ductile Iron |

| Impeller | Ni-Resist |

| Shaft | Carbon Steel |

| O-rings | FKM |

Performance Data

| Performance Data (50 & 60 Hz) | |

|---|---|

| Maximum Differential Pressure | 14 bar (203 psi) |

| Maximum Working Pressure | 30 bar (435 psi) |

| Hydrostatic Test Pressure | 70 bar (1,015 psi) |

| Minimum Temperature | -40°C (-40°F) |

| Maximum Temperature | 100°C (212°F) |

| Maximum Speed | 3,500 rpm |

Applications

- LPG transports – trailers and bobtails

- Bulk transfer and hose reel duties

- Self-loading or transfer via auxiliary inlet – without noise, vibration or significant wear and tear on pump internals

- Fixed installation – loading and unloading

- Cylinder filling

- Carousel filling operations

- Direct burner or vaporizer feed

- High-differential duties to 14 bar (203 psi)