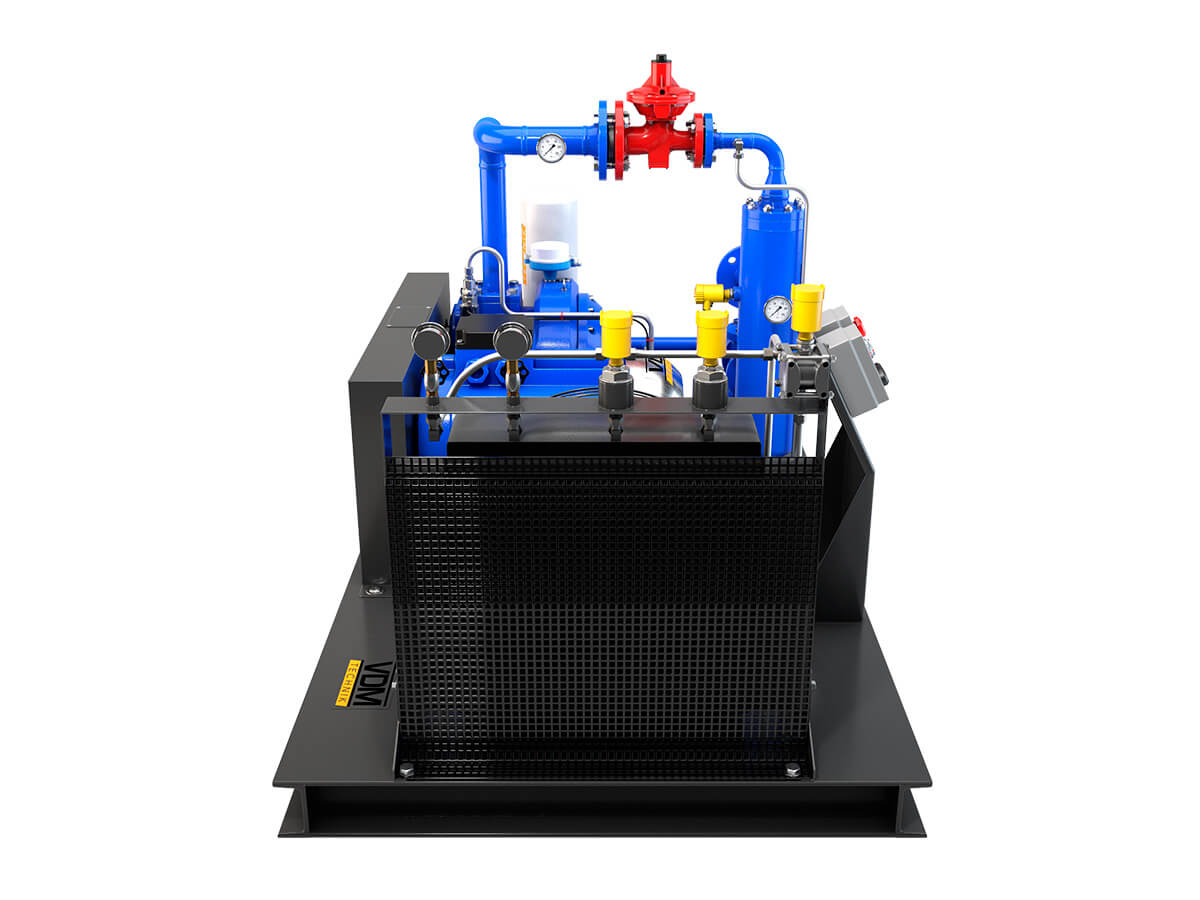

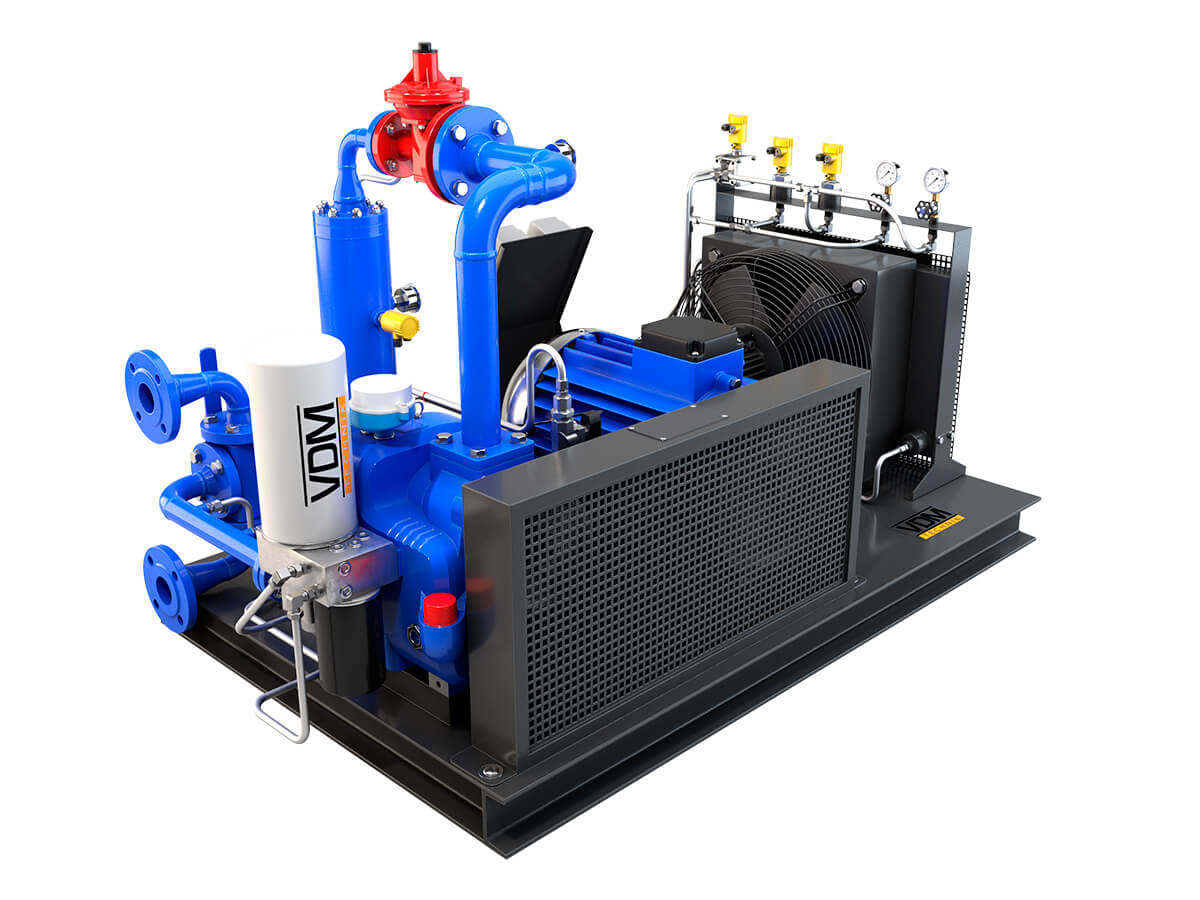

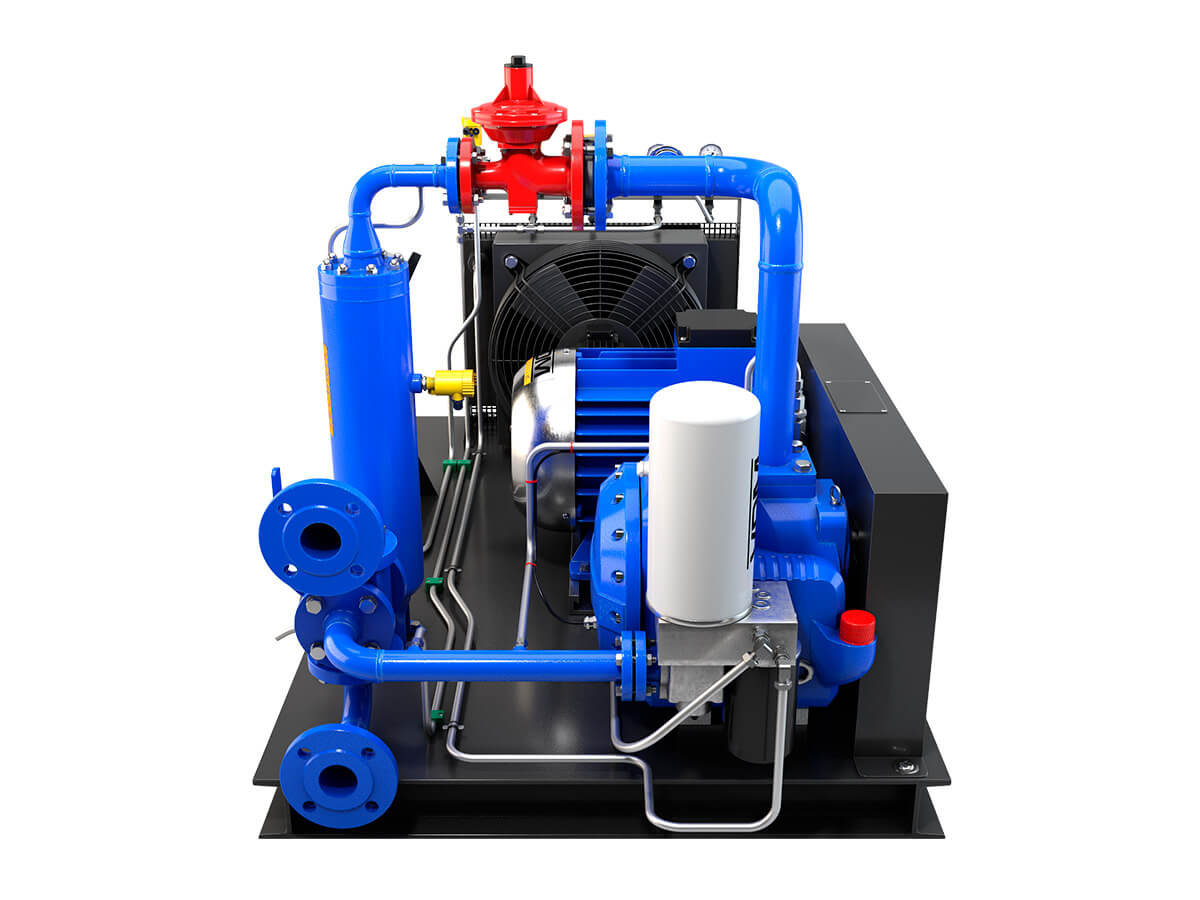

Screw-Type Compressor Unit VDM № 667.312 (200 m³/hour) for LPG

Screw-Type Compressor Unit for LPG pumping with a capacity of 200 m³/hour. Made in Germany.

Technical Characteristics

- Design pressure 18 bar;

- Compressor capacity at a differential pressure of 7 bar is 200 m³/h;

- Explosion protection class EExII;

- Explosion-proof electric motor 17.5 kW, 3000 rpm;

- The maximum rotation of the compressor shaft is 6000 rpm;

- Maximum differential pressure is 10 bar;

- Minimum screw compression ratio is 1: 3;

- Compressor unit RC200LPG;

- The screw compact module is equipped with a multifunctional unit, which includes an oil thermostat, an oil filter, separator cartridges for fine filtering, a minimum pressure valve, a back-pressure valve with a return oil line and a sight glass. The preliminary residual oil content in the gas is 1-3 mg per 1 m³ of gas;

- Coupling with plug for inlet pressure sensor;

- Coupling with plug for outlet pressure sensor;

- Sensor for monitoring the oil level in the compressor cavity;

- Coupling with a plug for the level sensor in the trap at the VEGASWING input;

- Temperature sensor PT100 of the working cavity of the compressor;

- Safety relief valve on the discharge line 16 bar;

- Four-way ball valve for changing the direction of movement of the product;

- Strainer on the suction line;

- Liquid phase and condensate Trap at the inlet;

- Pressure gauges at the inlet and outlet of the compressor;

- Connections: input and output flanges DN50, DIN2635.

Options

- Minimum pressure sensor;

- Maximum pressure sensor;

- Sensor in the Trap;

- Differential pressure sensor.

Electrical control panel for compressor unit

Basic execution of control panels includes:

- Main switch on the side wall of the control panel;

- Current leakage automated device at the input

- Emergency shutdown system with shock button connection terminals;

- Frequency converter with smooth start and stop of the motor;

- Oil Control in the compressor cavity;

- Terminals for connecting gas and fire sensors;

- Buttons for unlocking and disabling the signal on the front panel of the shield;

- Warning lights for unit operation status.

ATTENTION!!! Control panels for placement outside the hazardous area!!!

Options

- Minimum pressure sensor;

- Maximum pressure sensor;

- Sensor in the Trap;

- Differential pressure sensor.

* The arrangement of elements may differ from those shown in the pictures. FASENERGOMASH, LLC reserves the right to introduce technical changes.